Whether you’re just learning about CNC machines or have experience using a CNC spindle motor, there are several things you should do before using your tool. You’ll need to know how to clean the device and load the controller correctly. This information will also help you select the best tool for your needs.

Table of Contents

Cleaning the tool

Cleaning the tool using a CNC Spindler is crucial to ensuring accurate cuts and maintaining precision. To do this, you must completely disassemble and clean the tool thoroughly. The taper and tool holder should be free from chips and coolant and completely dry before reassembling. If the spindle is used repeatedly, you can use an oil-dispersing cleaner to remove the coolant residue.

When cleaning the tool, it is critical to avoid using solvents, as they can cause corrosion inside the spindle’s bore. This corrosion can also corrode the collets and precision-ground surfaces. When this occurs, the collets will tend to run out and over-torque.

Checking the working condition of a CNC spindle motor

During maintenance, it is essential to check the working condition of your CNC spindle motor. If it doesn’t run smoothly, it might signal an electrical issue. Here are some steps to prevent the motor’s working condition: First, unplug the CNC spindle from the main power supply. Then, remove the sheet metal cover. You can then examine the motor’s speed control.

If the voltage in the control cabinet is too high or too low, you need to check the internal connections of the spindle motor. This can be done by using a multimeter. You should also check the resistance of the connectors and contacts. If you have a REGEN or Vector Drive, ensure the resistors are set correctly.

Checking the Load on the Controller

Checking the load on the controller when using CNC spindle motors is an essential aspect of machine maintenance. It is crucial to ensure that the spindle motor is working correctly to ensure that the machine is safe and efficient. In addition, you should run a warm-up program on the spindle before a shift starts. This will help the spindle stay spinning. You should contact maintenance or spindle repair services if the spindle begins making unusual noises.

The controller should display the target voltage (230 VAC). The spindle motor may not achieve its maximum RPM if the voltage is too high or too low. In addition, bad connections may lead to high and low DC errors. In such a case, you should check the connections of the L1, L2, L3, and GND to avoid any phase loss. Impedance can also cause errors and cause the motor not to work at its maximum RPM.

Choosing a Tool

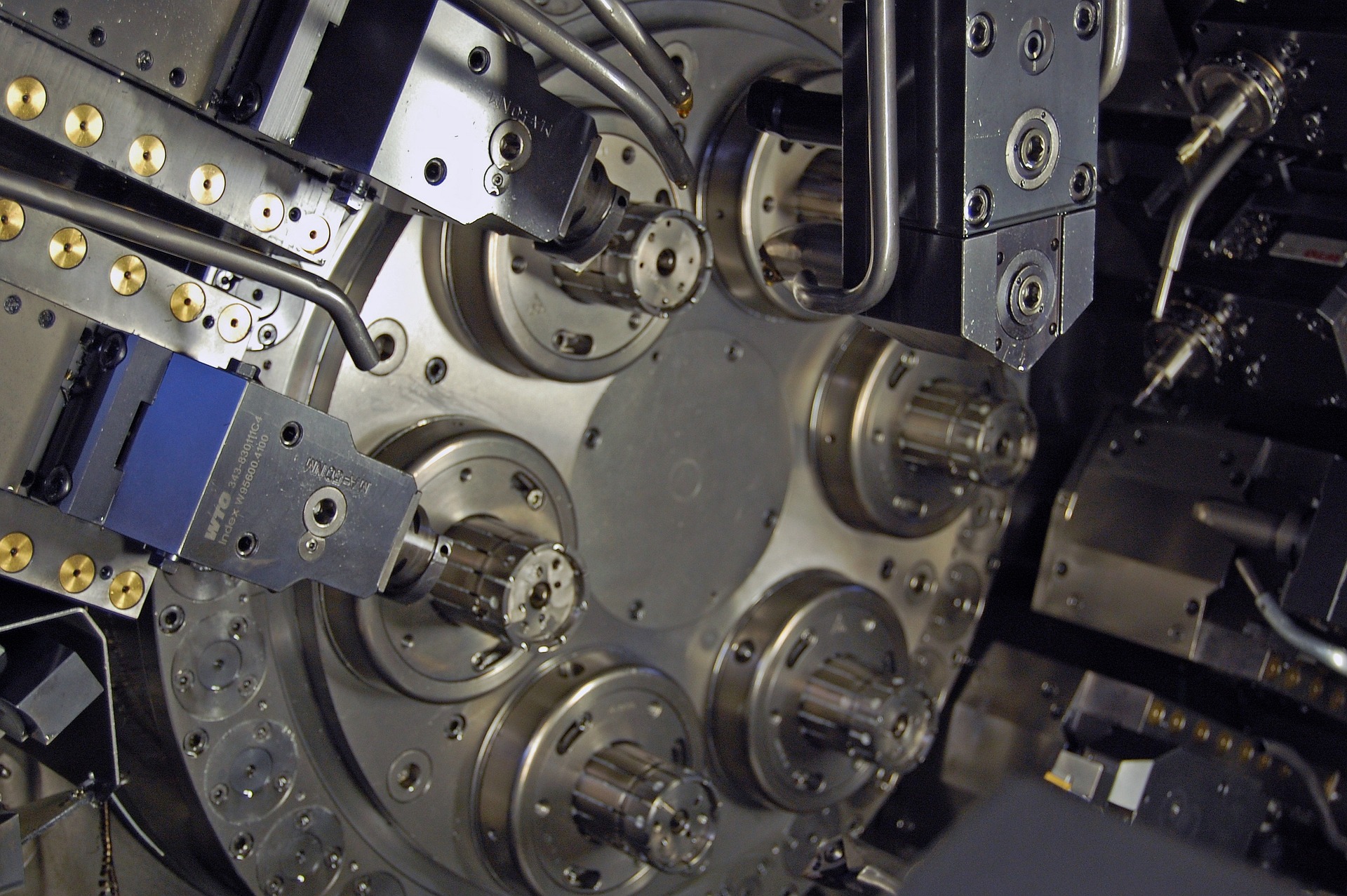

Choosing a spindle is one of the most important steps in a CNC job. It ensures you get the right speed, power, and torque balance. You’ll need to consider the motor, spindle construction, and speed range when choosing a spindle.

CNC spindles are available in different types, each with its features. For instance, an aluminum construction spindle is ideal for engraving and cutting soft materials, while steel or cast iron spindle is better for CNC milling hard metals. Nevertheless, steel and cast iron spindles are more expensive than aluminum spindles.

Checking the Feed Rate

The feed rate is one of the most important things to check when using a CNC spindle motor. This will determine whether you can mount the engine to the CNC router or not. Also, check the shape of the spindle. Are you using a square spindle or a cylindrical one?

Checking the feed rate is also essential if you need to adjust the speed of the spindle. Some spindles go as high as 18,000 rpm, and you need to choose an appropriate feed rate for the material you are cutting. The spindle speed and feed rate will be directly proportional to each other. The feed rate will need to be adjusted if you need to make a more profound or broader cut. Using a high feed rate will also require more power.

Choosing a Tool Holder

Choosing a tool holder is a critical component of CNC machining. Using the right tool holder for the job is vitally important, but it is often overlooked. The right tool holder for your CNC spindle motor will provide maximum tool gripping force close to the workpiece, minimize tool overhang, and provide repeatability. There are two main types of tool holders: solid and hollow. Solid ones have a larger surface area, while hollow ones have a smaller one.

A CNC spindle motor must be powered by a proper power source, which will help you get the best results. You should select one with adequate cooling and RPM. It would help if you also chose a spindle for the material you are machining. Wood and aluminum require 24,000 RPM and 1kW of power, while steel requires between 15,000 and 18000 RPM and 5.6 kW. The right spindle motor type for your work depends on your tools and size.

Checking the Pressure Cap

Checking the pressure cap when using a spindle motor is essential for ensuring the motor is working correctly. Too little preload can lead to skipping the balls, and too much clamping load can distort the races. To check if the pressure cap is tight enough, remove the front lid and check its clearance with the spindle shaft using a 0.001″ shim stock. The front cap may have rubbed the spindle shaft if it is still closed.

Checking the pressure cap before using a CNC spindle motor is an excellent way to protect the motor from damage. When the pressure cap is too loose, it will cause the spindle to overheat. To prevent this, use the proper lubricant and set the pressure cap correctly.